We understand that all labs are different, so while we’ve designed our products to be as flexible as possible, sometimes you’ll need something unique to your lab or application.

The Syrris R&D Team regularly work with customers across a range of industries to design, prototype, test, and build custom parts for our batch, flow, and scale-up chemical reactor systems.

What custom parts are available?

Over the years the Syrris R&D Team has developed a range of custom parts – from stirrers, vessels, condensers, and other glassware – through to entire custom systems. We manufacture our own glassware so have complete flexibility.

Use the contact form to speak to the Syrris team about your specific applications and requirements.

Contact us to discuss your custom requirements

The custom parts process: A custom stirrer case study

An innovative company looking to revolutionize the washing machine industry through the use of polymer laundry bead cleaning approached Syrris to design a stirrer system that would mix 50 kilograms of their polymer beads to aid in their research and development. The custom stirrer was to be used with an Orb Pilot scale-up chemical reactor system in a 50 L vessel.

Feasibility study

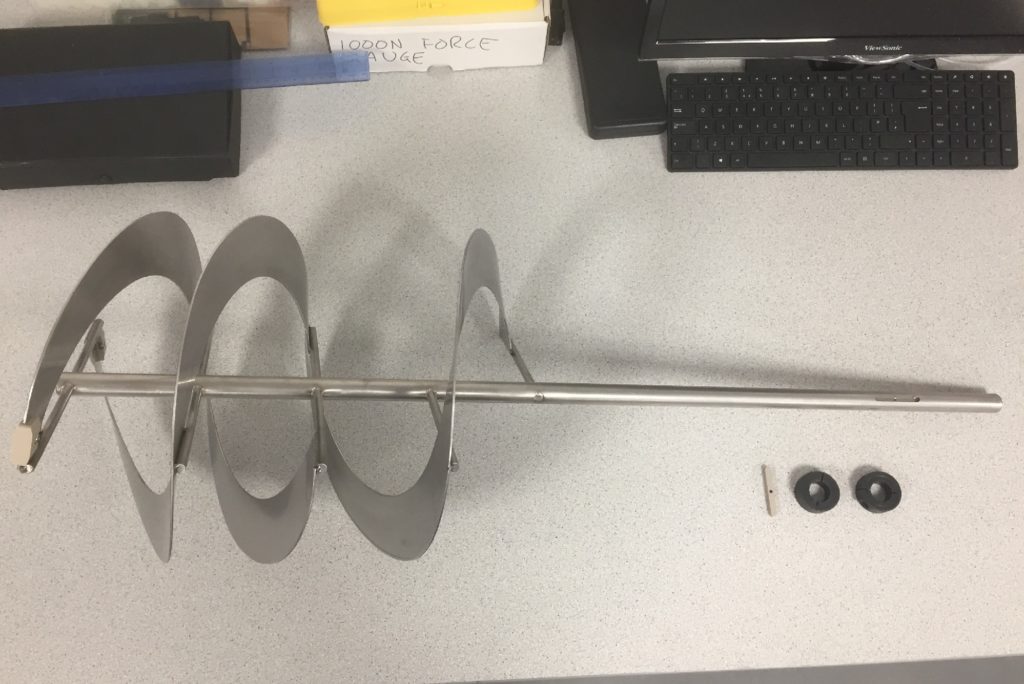

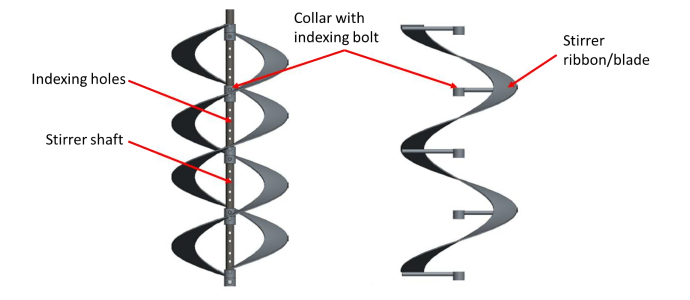

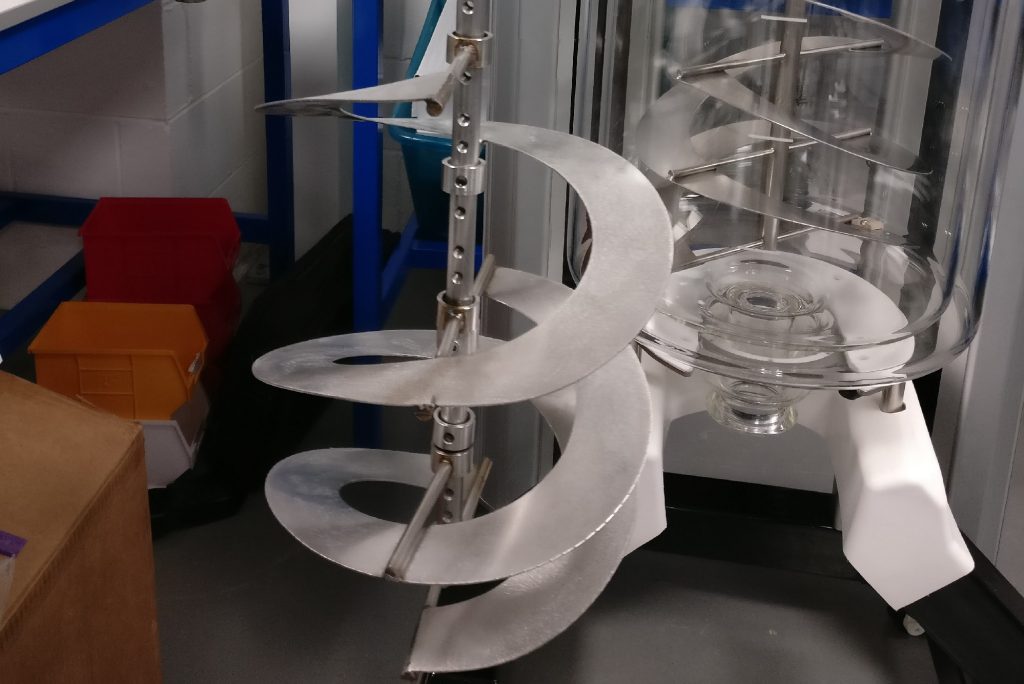

We designed a helix-style stirrer and sent a document to the customer for approval prior to fabrication. The prototype was designed in a way to enable multiple single, double, and half-height helix configurations to be trialed for mixing and optimizing torque to speed ratio. A gearbox system was also designed to convert the stirring speed from the motor at a ratio of 5:1.

Prototype

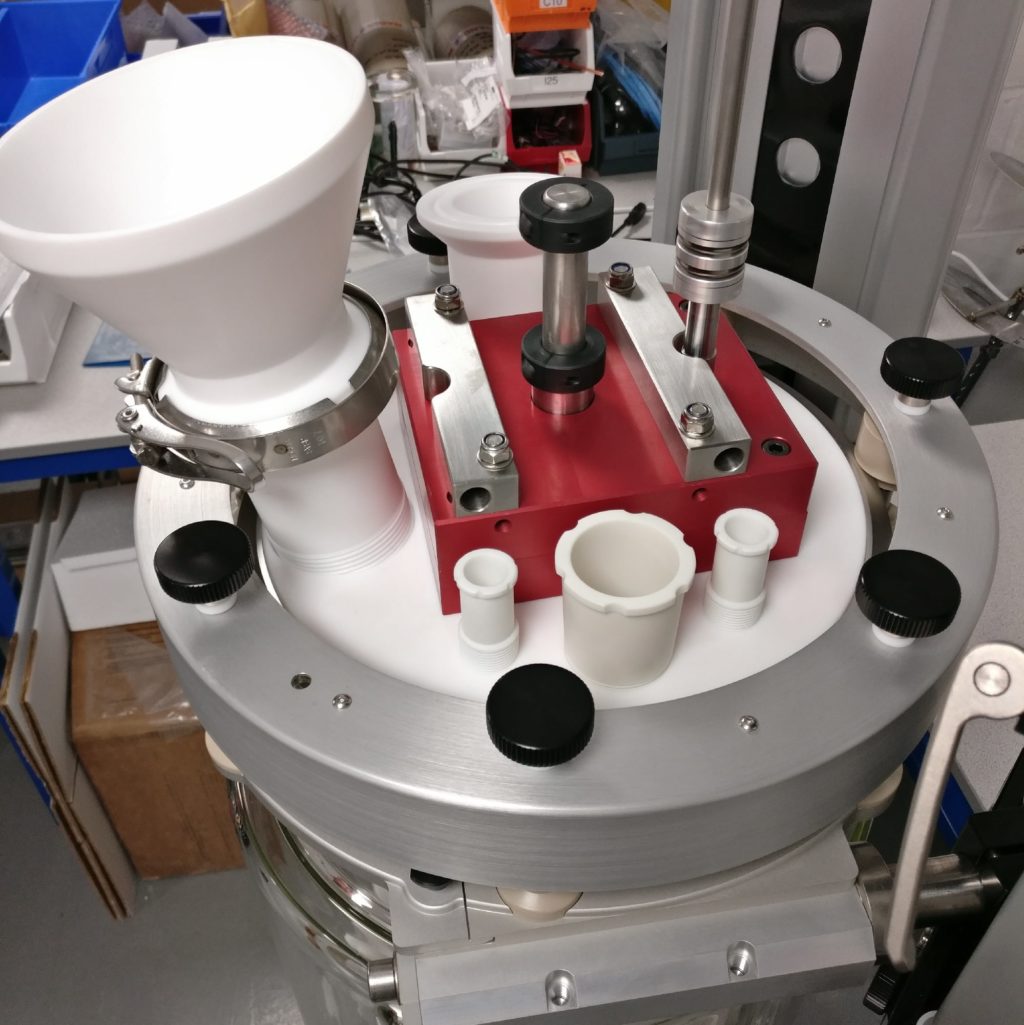

Following sign off from the customer, we manufactured and tested the stirrer. This included making a test rig including a gearbox and test lid. The prototype was built with multiple indexing holes along the stirrer shaft; this enabled the R&D Team to test the mixing performance of single, double, and half-height helix configurations at varying angles.

Final design

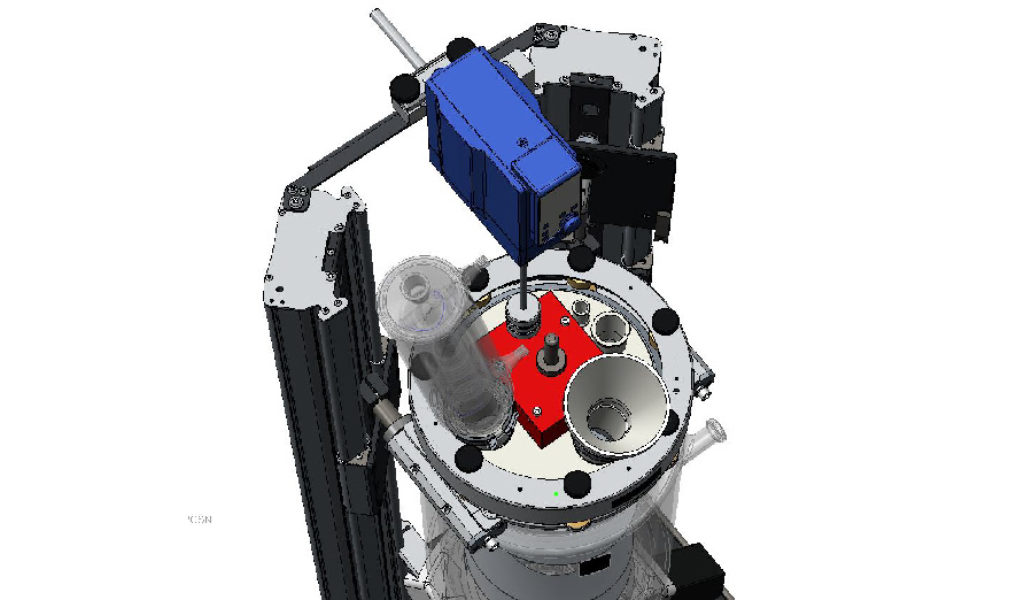

Following completion of the feasibility study and identifying the best design for the custom stirrer based on the customers’ mixing requirements, the production custom lid, stirrer, and gearbox assemblies were designed and CAD images were sent to the customer for approval. A flexible joint in the stirrer shaft was added to the design to offer some tolerance in stirrer motor alignment with the gearbox.

Production

Following sign off, manufacturing drawings were completed, the parts manufactured, and the system built and tested. Instructions were also provided as an addendum to the Orb Pilot manual to cover the use of the custom parts.

Contact us to discuss your custom requirements

Use the contact form to speak to the Syrris team about your specific applications and requirements.

Customer success story

The Kuwait Institute for Scientific Research (KISR) approached Syrris to manufacture a unique custom reactor system (CRS) for the Institute’s Petroleum Research Center. KISR is a national institute of science and technology engaged in developing practical solutions to problems such as the preservation of the environment and sustainable management of Kuwait’s natural resources, as well as supporting the growth of national industries. The custom reactor system was needed to aid in researching the deformation of polymer samples under supercritical conditions, for applications in the petrochemical tubing field.

We needed a custom reactor system, and Syrris followed our proprietary design to manufacture a one-of-a-kind prototype custom reactor system for us. We have had the custom reactor system for several months now, and are really pleased with it.”

Dr. Salah Al-Enezi, Associate Research Scientist, Kuwait Institute for Scientific Research (KISR)